Catari US® - Universal System

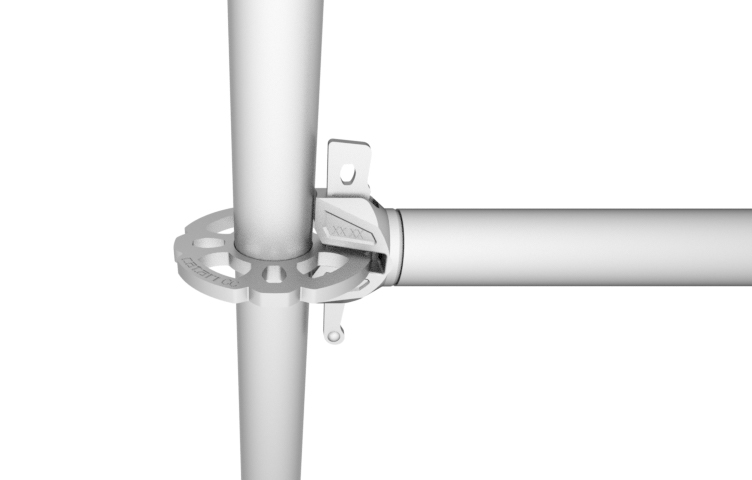

Catari US® is a multidirectional ringlock scaffolding system based on the rosette design, engineered for maximum efficiency and performance.

Each component has been optimized for functionality, weight, and load capacity, ensuring enhanced safety and long-term reliability. Exceptional versatility and load-bearing strength make it ideal for even the most complex and demanding scaffold constructions, including heavy-duty industrial and civil engineering applications.

Designed to meet the challenges of modern construction, the Catari US® ringlock scaffolding system delivers superior precision in every project.

New Generation of Catari US®

Harder

Made from high-tensile steel, the scaffolding parts have enhanced structural integrity, ensuring greater resistance and durability.

Better

Redesigned with innovative shapes, such as self-locking features and swivel wedges, the system’s components make assembly easier, quicker, and safer.

Faster

Increase your team’s productivity. Lighter parts allow for quicker movement, making assembly and dismantling easier and more efficient (12%), also reducing strain and risk of injury to workers.

Stronger

With a reinforced steel structure, we have significantly increased the load capacity, allowing you to build higher and stiffer structures. Through a high-tensile type of steel, the structural integrity of the ringlock scaffolding system has been enhanced, ensuring greater resistance and durability.

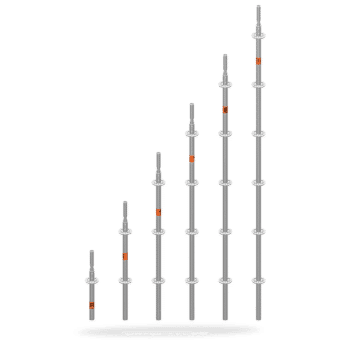

Redesigned Standards for next-level performance

Monobloc design

Manufactured with high-tensile steel, the new standards are stronger than ever, delivering increased load capacity and superior durability. Both the tube and the rosette have been reinforced to meet the demands of high-performance scaffolding. The tube and spigot are now a single seamless piece, reducing overall weight and optimizing production time. In addition, the rosettes now feature visible markings for easier verification on site.

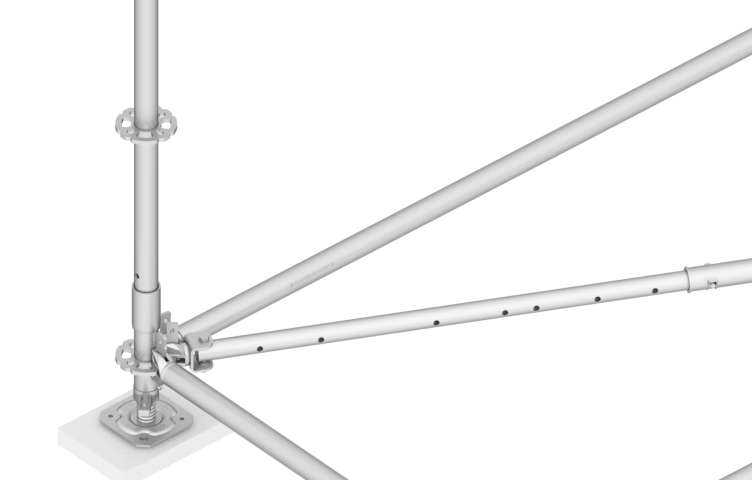

Engineered for Stability

The redesigned base of the Catari US® standards ensures a more precise and secure connection during assembly. This improved fit enhances overall scaffold stability, reducing movement and increasing safety on site even under demanding conditions.Featured Components

Standards

Reinforced tube and rosette boost strength and load capacity, while the spigot and tube are now a single piece for weight optimization.

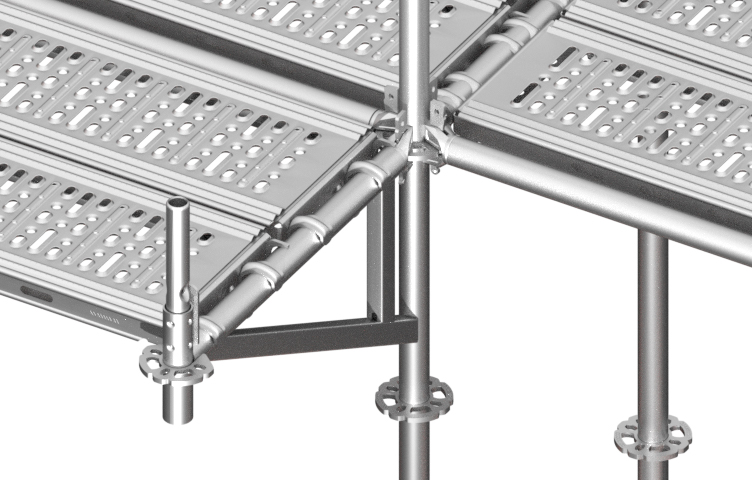

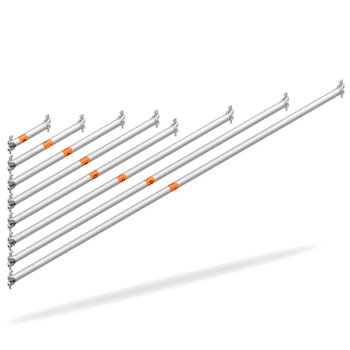

Ledgers

The expansion of the range allows for greater compatibility with all systems, including metric ones.

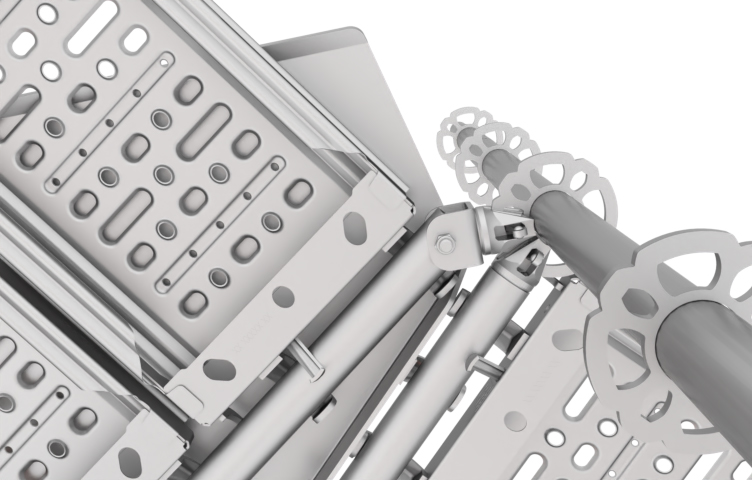

Decks

Different profile heights for an optimised weight.

Maximized efficiency, reduced costs

Our ringlock scaffolding system is designed for faster assembly and reduced costs. The locking wedge replaces traditional screwed connections, simplifying installation and cutting down on labour needs. With multi-purpose scaffold components, material requirements on-site decrease while utilization rates improve. Additionally, the galvanised finish and non-detachable wedges increase durability, minimizing maintenance and ensuring long-term performance. A smart solution for efficiency, versatility, and long-term savings.

Quick assembly

Catari US® features base collars that allow a single person to align the scaffold safely. Its rigid fitting and wedge blocking mechanism ensure secure linear and angled connections, quickly and without bolts or special tools. With a consistent assembly workflow, regardless of configuration, scaffolders benefit from shorter learning times and improved efficiency on-site.

Safety at every stage

Tested anchorage points provide secure harness attachment during assembly and disassembly, while guardrails every 50 cm and perimeter toe boards ensure a safer working environment. The wedge locking mechanism transforms unblocked connections into solid joints with a simple hammer blow, distributing forces efficiently for high load-bearing capacity. Additionally, Catari US® multidirectional scaffold system complies with European scaffolding standard EN 12810-1, guaranteeing rigorous external testing and reliable performance.

One scaffold, multiple applications

Since the main components of every scaffold configuration are the same, Catari US® follows just one logical assembly sequence regardless of the application. As a result, any basic assembly can be achieved just repeating few steps.

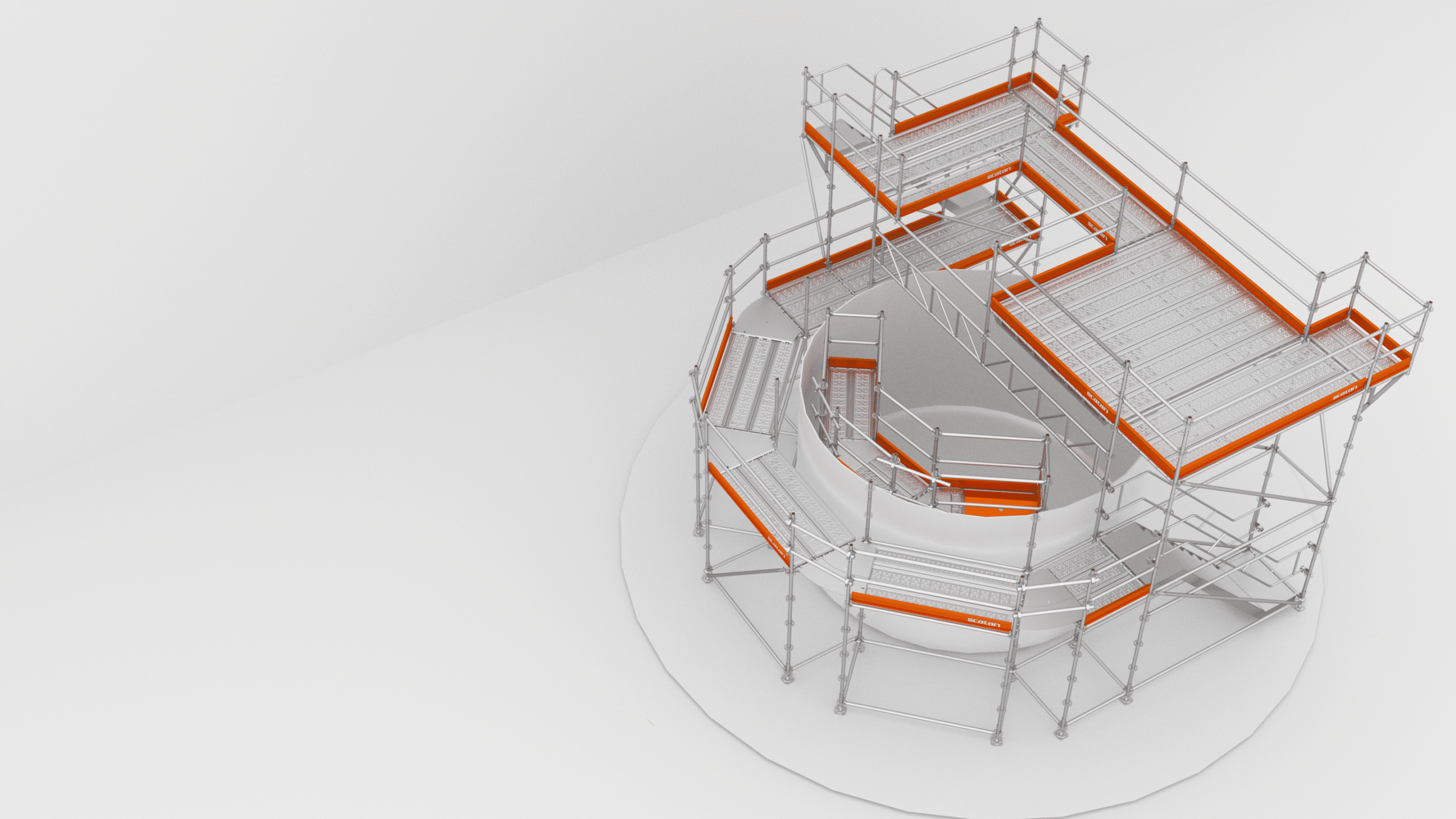

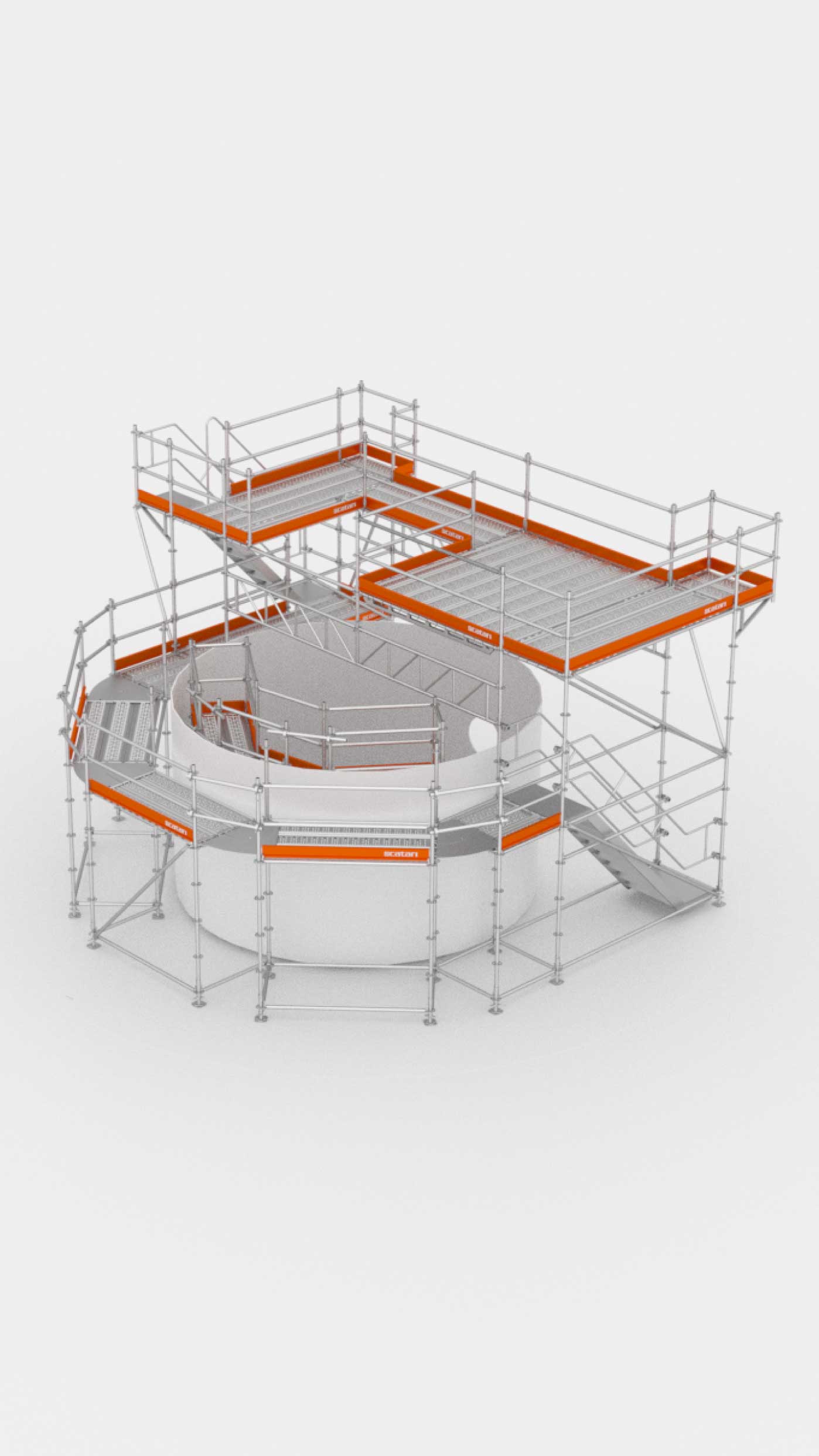

The ultimate solution for Industrial Maintenance

Catari US® is specifically designed for challenging environments, such as narrow spaces, circular tanks, and furnaces. Beyond its versatility and top-tier load capacity, the system features components specially developed for industrial applications. The foldable access deck allows for easy assembly in hard-to-reach areas while minimizing the risk of falls. The swivel ledger is engineered to offer flexibility, adjusting to any angle for precise scaffolding configurations. Combined with angular steel decks and ledgers, it ensures seamless adaptation to various industrial setups, including tanks and silos.

With its robust design and specialized features, Catari US® delivers both safety and efficiency, making it the ideal choice for industrial maintenance projects.

Download components listScaffold mobile towers

For sequential works, fasten the adaptor for castor wheels and convert a standard configuration into a mobile scaffold. The twin breaks assure the safety of the structure while parked.

Download components listRinglock scaffolding stair towers

When on-site temporary access is required, scaffold stair towers can quickly and safely be assembled using the standard components of Catari US® ringlock scaffolding and pre-assembled aluminium stairways elements.

Download components listFreestanding scaffold

The system enables the assembly of freestanding scaffolds, offering clear, anchor-free access to formwork or wall rebars. Stability is achieved through a widened base (buttress) and, if necessary, counterweights. Its flexible bay lengths ensure full access to all key components, while adjustable widths allow for seamless integration with limited on-site space. Inner guardrails and brackets provide secure working conditions, even in cases where there is a significant gap from the wall.

Download components listBirdcage scaffolding

Catari US® allows for the assembly of birdcage scaffolding, providing safe access to elevated work areas during construction or maintenance activities in buildings and industrial facilities. Perfect for repairs and painting on high ceilings, this solution ensures both efficiency and safety, making work at heights easier and more secure.

Download components listSuspended scaffold

Catari US® portfolio features highly resistant beams and a wide set of accessories that ease the assembly of slung scaffolds while ensuring the scaffolders and end-users safety.

Download components listPublic stairs

Catari US® Public Stairs offer versatile assembly options to meet job regulations and audience needs. Whether overcoming obstacles or providing pathways to grandstands and stages, these stairs deliver a flexible solution. With high load capacity and a hot-dip galvanized finish, they ensure a safe, long-lasting structure for public use.

Download components listCustomised layout grid

Intermediate ledgers, deck to deck, tube to tube and tube to deck or console brackets and adjustable horizontal braces can be used to create tailored spans, thus ensuring the scaffold fits the available space and avoids existing infrastructure constraints.

Download components listProject design

Erecting a scaffold in multistorey buildings or in industrial contexts, such as tanks, silos, racks, etc., can be challenging due to the constraints of the site. To overcome these limitations, the engineering team of Catari develops tailor-made solutions using 3D modelling for improved visualization of the final solution. Additionally, detailed calculations, technical support, and shop drawings are provided to ensure structural integrity, safety, and compliance throughout the project.

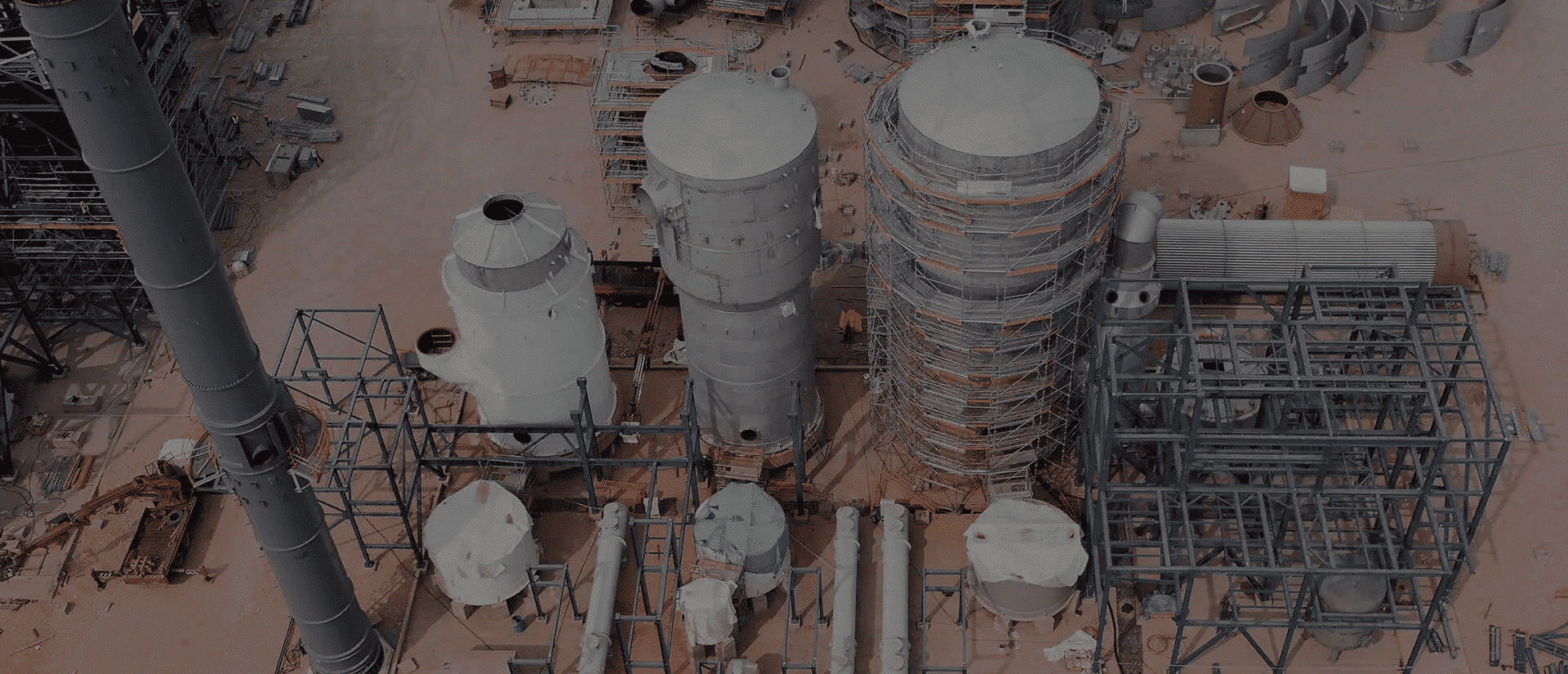

Download components listLimitless Projects

Empowering innovative solutions that adapt to any challenge, backed by our ringlock scaffolding system’s versatility and our internal ability to meet market demands, while ensuring sustainable and efficient construction.

Scaffolding as a branding solution

Transform scaffolding structures into a billboard solution with our innovative design. This approach provides a clean, functional surface that completely covers the scaffolding, turning it into a spacious area perfect for communication and branding. It’s a creative way to utilize scaffolding while adding value through effective advertising.

Download components listRinglock scaffold assembly with innovation

Improve the process of assembling suspended scaffolds, focusing on increasing safety and precision. By simply adding one component you can transform your Catari US® – Universal System into an advanced suspended scaffold solution. This innovative approach opens up a range of applications, from bridges and obstacle circumvention to areas without ground support, allowing you to tackle complex projects with ease and confidence.

Download components listExplore the compatible systems

Catari US® Public Stairs

Temporary scaffold staircases Public Stairs

Catari US® Public Stairs is a scaffold stairs system that provides access stairs for the general public.

Catari UMBRA

Keder Roof System UMBRA

Catari UMBRA is a state-of-the-art modular temporary roof scaffold system engineered to provide unmatched shield against inclement weather conditions.Projects References

See our reference projects.