Rehabilitation of Madrid’s Atocha Train Station: Phase 2

ATES relies on Catari US® for a challenging project at Madrid’s iconic train station.

ATES relies on Catari US® for a challenging project at Madrid’s iconic train station.

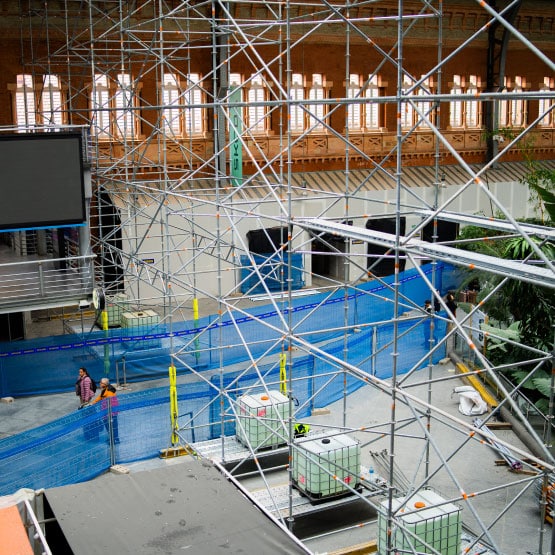

The second phase of rehabilitation work at Atocha Station is already underway. ATES is implementing a scaffolding structure using the Catari US® multidirectional system, designed to support a large-format advertising banner while also enabling restoration work in Madrid’s Tropical Garden.

The solution ensures that the intervention proceeds safely and efficiently, without disrupting the daily flow of thousands of passengers using the station.

Built with Catari - Atocha Train Station

On-site, Catari spoke with Miguel Ortego, Central Zone Delegate at ATES, who provided detailed insights into the ongoing works.

We invite you to explore the main highlights of this intervention and watch the video “Built with Catari – Atocha Project”, which showcases every detail of this demanding undertaking.

The current intervention features a scaffolding structure built to support a large concealing banner. This banner ensures that the restoration inside the Tropical Garden proceeds discreetly, without affecting the station’s regular operations—one of the busiest transport hubs in Madrid.

The scaffolding was carefully designed to be as narrow and efficient as possible, with anchoring at only two edge points and the roof. This setup required meticulous engineering calculations to ensure stability, safety, and material optimization.

Beyond technical requirements, the project faced an additional challenge: an extremely tight execution timeline. ATES needed a solution that would meet the deadline without halting access for the station’s thousands of daily users. The answer came in the form of a phased installation—first on one side (allowing circulation on the other), and then vice versa—ensuring uninterrupted public access at all times.

Miguel Ortego

Central Zone Delegate at ATES

Focus on stability and safety

To ensure structural safety, tension belts and ballast tanks were installed at the base, reinforcing stability and preventing any risk of displacement or collapse. These measures were essential to meet the structural demands of the project.

We thank ATES for their trust and cooperation in this landmark project. This is yet another success story that highlights the versatility, reliability, and performance of the Catari US® multidirectional system – even in the most technically and logistically demanding scenarios.